Let us design a dredge to meet your needs!

General Types and Descriptions:

No two mining operations are the same. Thats why Supreme Manufacturing offers custom dredge design. If you can dream it, we can build it.

ADVANTAGES OF CLAMSHELL DREDGING:

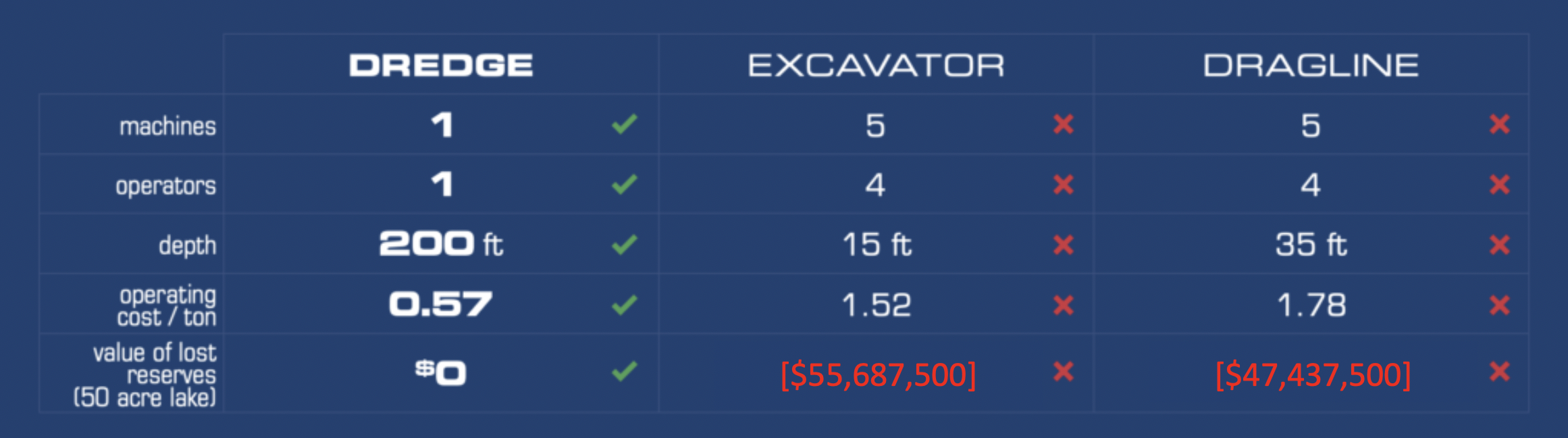

- Depth capability. They are typically designed for 200’ feet of mining depth. There are several machines in service today digging more than 300’. Deeper designs are possible.

- Increase reserves and the ability to re-open existing properties that are already permitted

- Increase land value

- No loss of fines

- Able to extract large size particles

- Reduce material handling costs

- Eliminate diesel use when designed for all electric

- Reduce manpower

- Increase efficiency

- Improve material flow

- Ease of re-sale with high residual value of equipment

IDEAL APPLICATION:

An ideal application would be an alluvial deposit of sand and gravel found in glacial areas and river basins, typically with a deposit depth greater than 25 feet. Another ideal location is near urban areas where deposits run deep and producer is surrounded by development.

ONBOARD PROCESSING OPTIONS:

- Dewatering Systems - Most clamshell dredges are equipped with material dewatering systems consisting of a double/triple deck horizontal screen. Top deck usually carries the larger gravel. Bottom deck is the dewatering deck. Size is dictated by customer needs and other equipment onboard (i.e. FSR, etc).

- Fine Sand Recovery - This is a system to capture fine material to as small as 200 mesh. Equipment required: vertical pump, cyclone, high frequency dewatering screen, support structure and piping.

- Rake Grizzly - Positioned above the hopper. This option allows the operator to “rake” oversize material and clay to a barge or onboard crushing system. **This system is not compatible with deposits of flat rock.

- Dump Grizzly - This grizzly is designed with square openings. It is operated by hydraulic cylinders.

- Onboard Crushing - The onboard primary crushing has become more popular. Typically a jaw crusher is used, but some systems may utilize impact crushers.

- Hydraulic Rock Breaker - Typically used in conjunction with an onboard crushing system. This allows the operator to limit the size of material before sending it to the crusher and to clean the grizzly.

- Spray Bar Systems - Used where deposits are high in fine material or clays. These systems help wash out unwanted material.

- Wash Down Systems - For washing the pontoon decks and conveyor transitions.

- Material Pumping System - If replacing a hydraulic dredging system to maximize depth in a deposit… a customer may want to retain the existing land-based plant. The clamshell system can be designed to accommodate a material pumping system. This requires a change to the screening process. Rather than a dewatering screen, we utilize a simple scalping screen, which screens at approximately 4”. All minus 4” material is sent to a sump tank and pumped to the plant using a pump and floating pipeline.